This article provides an in-depth description of on-metal RFID tags, outlining their features and applications.

What are on-metal RFID tags?

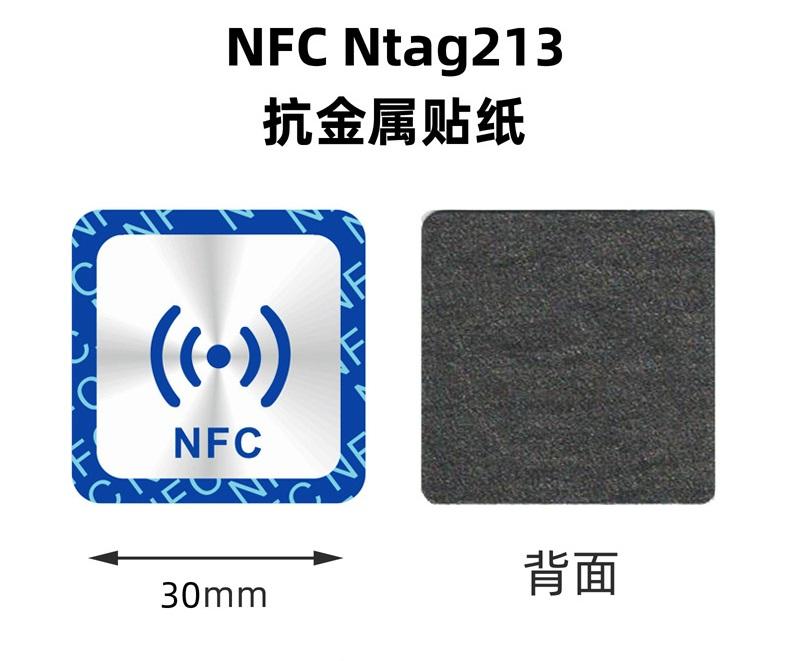

On-metal RFID tags are specialized RFID devices designed to function effectively when attached to metal surfaces. These tags address the challenges that traditional RFID tags face, such as signal interference and poor read range when near metal.

Their ability to overcome traditional RFID limitations makes them invaluable in environments where metal is prevalent. It is a crucial technology for industries that require reliable asset tracking and management on metal surfaces.

Features of On-Metal RFID Tags

Here are some features of On-Metal RFID Tags:

- Enhanced Read Range. On-metal RFID tags are engineered to achieve a longer read range compared to standard RFID tags. This is accomplished through specific design techniques that utilize the metal's properties to enhance signal strength and minimize interference.

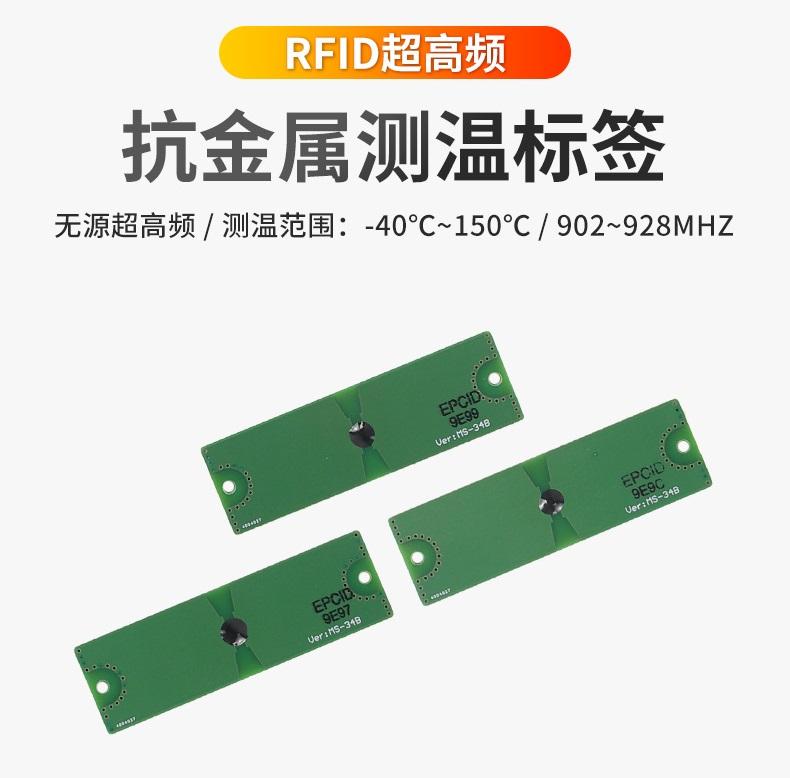

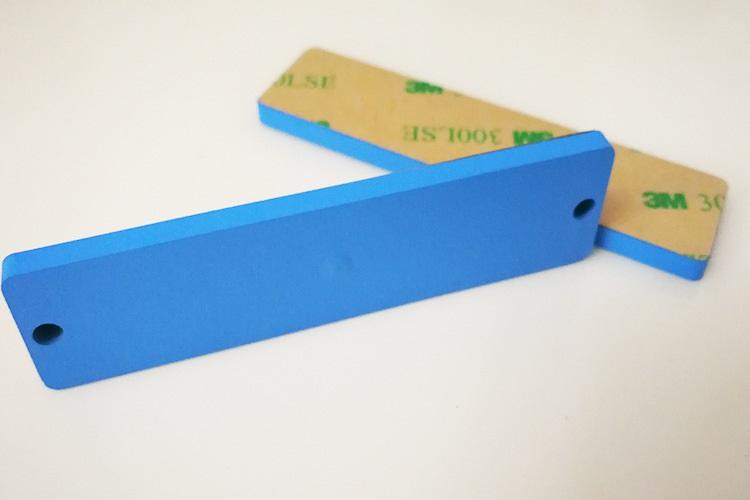

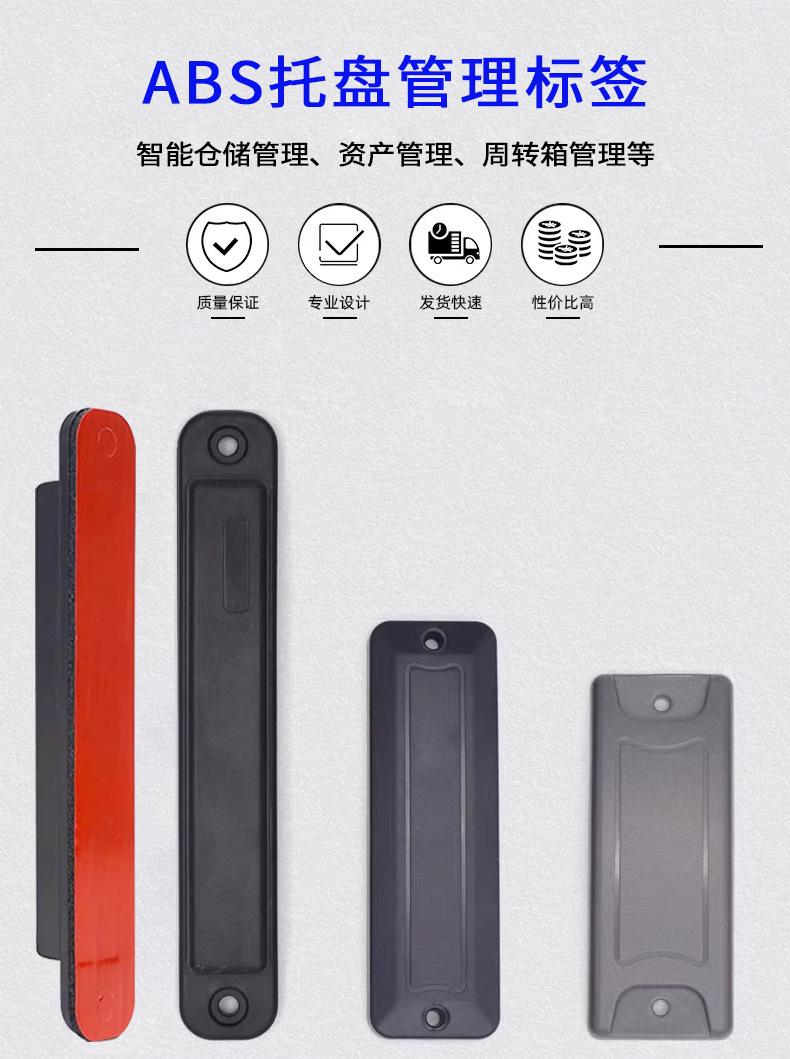

- Durability. These tags are built to withstand harsh environments, including extreme temperatures and physical abrasion. They are often encapsulated or designed with robust materials to ensure longevity in demanding conditions.

- Variety of Form Factors. On-metal RFID tags come in various shapes and sizes, including self-adhesive labels and hard tags. This versatility allows them to be used in diverse applications across multiple industries.

- Compatibility. They are compatible with various RFID systems, including passive and active tags, and can be used in conjunction with different RFID readers and antennas.

Applications of on-metal RFID tags

On-metal RFID tags are widely used in various industries.

Asset Tracking

They are commonly used to track metal assets in sectors like aerospace, automotive, and healthcare. For instance, the U.S. Marine Corps employs these tags to monitor military equipment such as tanks and trucks.

Industrial Manufacturing

In manufacturing environments, on-metal RFID tags help in quality control and inventory management by providing real-time visibility of assets.

Oil and Gas

These tags are effective for tracking equipment and materials in oil and gas operations, where metal surfaces are prevalent.

Tool and Equipment Management

They are also used for tracking tools and instruments, which can be challenging due to their size and shape.

Operational Principles of on-metal RFID tags

On-metal RFID tags operate by compensating for the effects of metal, which can detune and reflect RFID signals. The design methods include:

- Spacer Design. Early designs used spacers to shield the antenna from direct contact with metal surfaces, enhancing read range and reliability.

- Specialized Antenna Design. More recent innovations focus on antenna designs that leverage metal interference to improve performance, allowing for smaller tags that still maintain effective communication.