On-Metal UHF RFID Tags

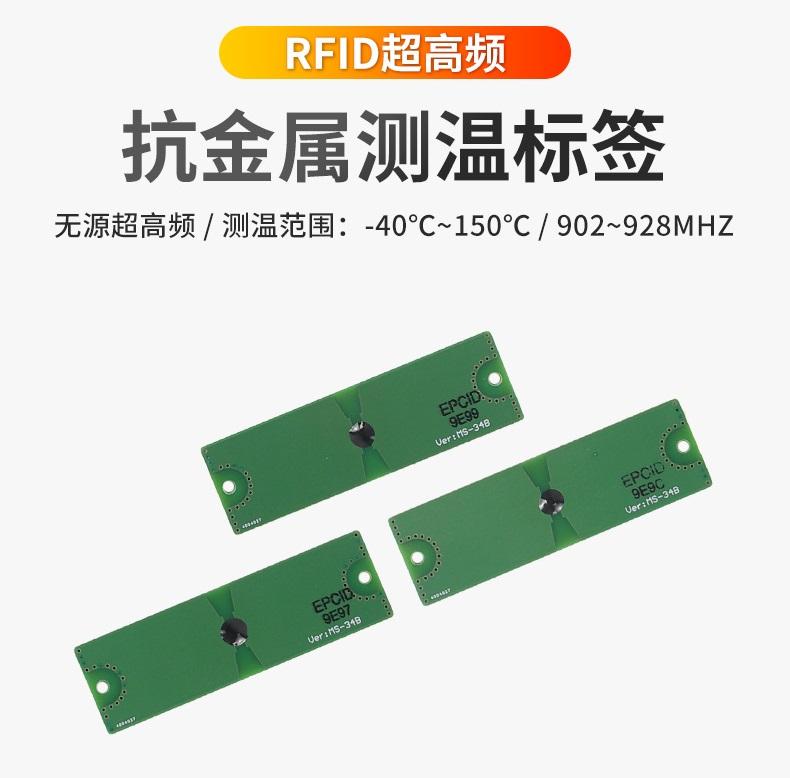

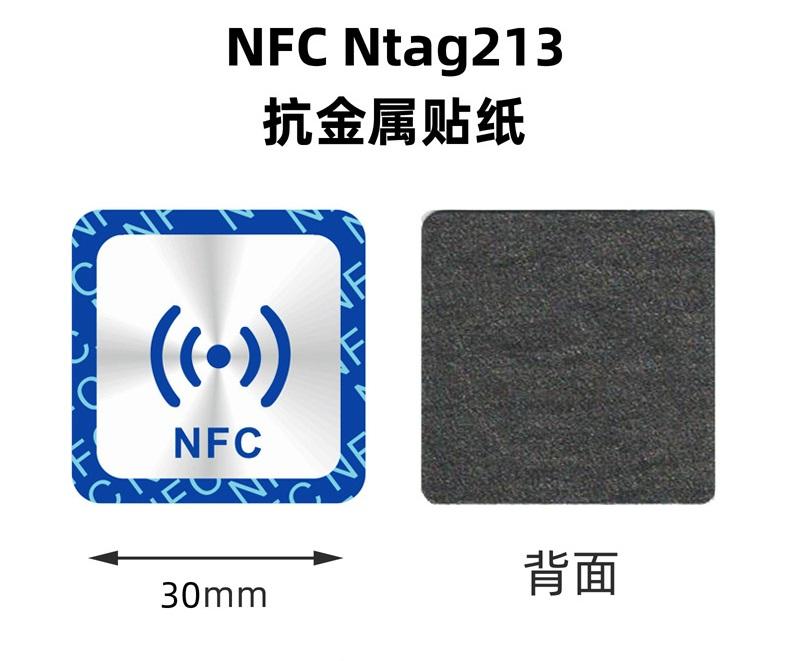

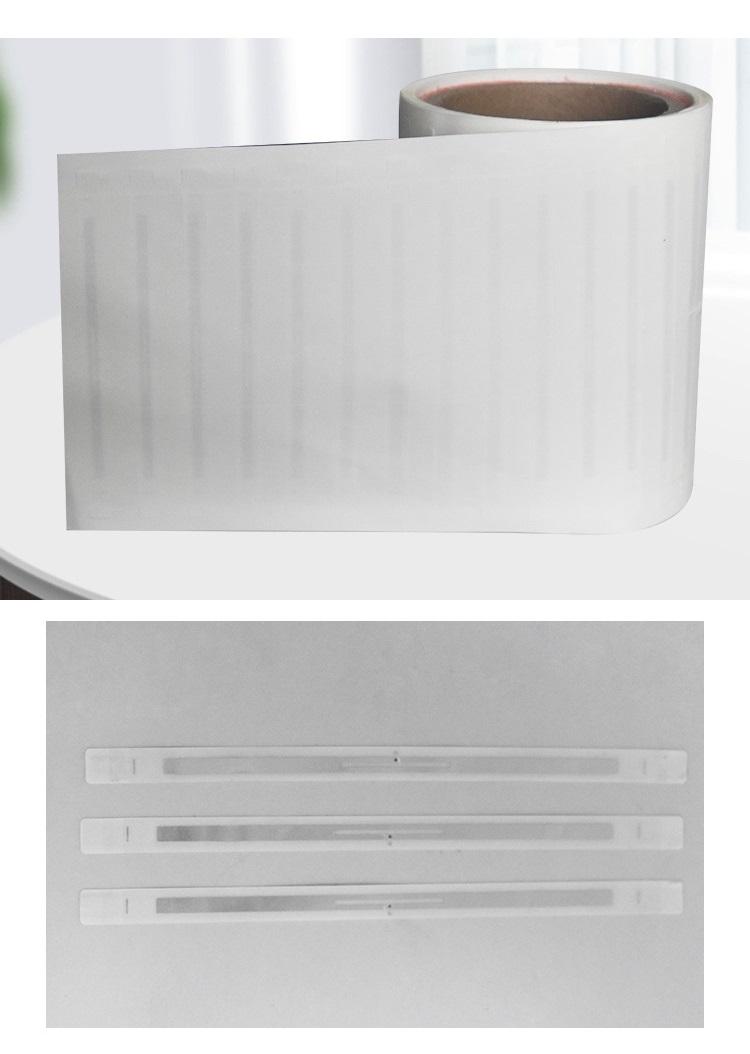

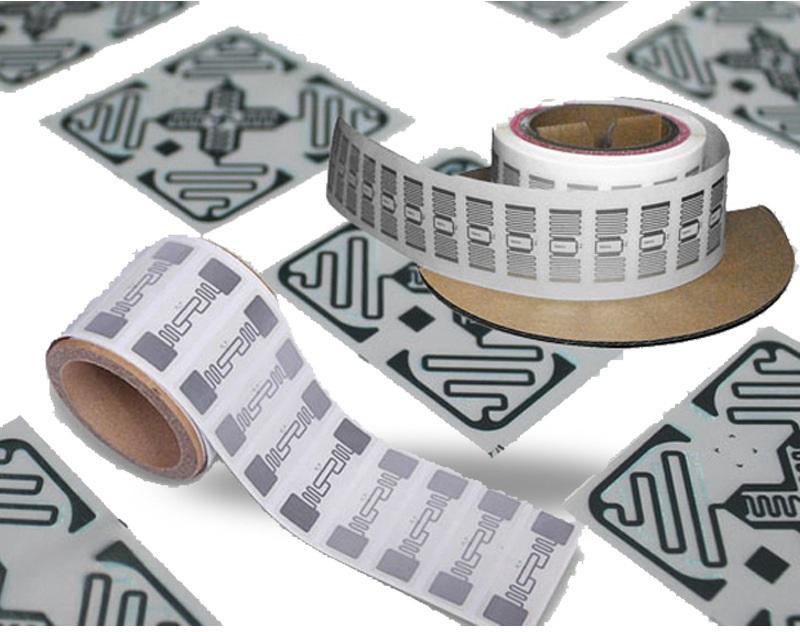

On-metal RFID tags are specialized RFID tags designed to function effectively when attached to metal surfaces. Traditional RFID tags typically perform poorly or fail entirely when placed on metal surfaces due to interference and signal detuning. On-metal RFID tags solve this by being engineered specifically for such environments.

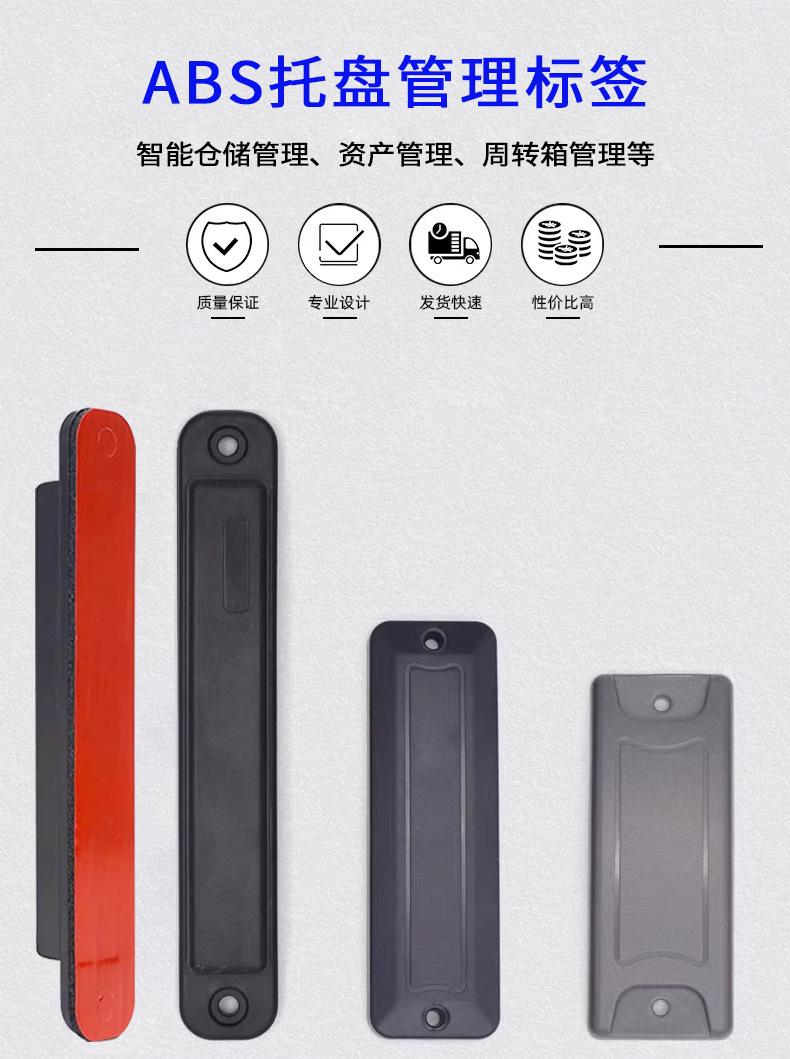

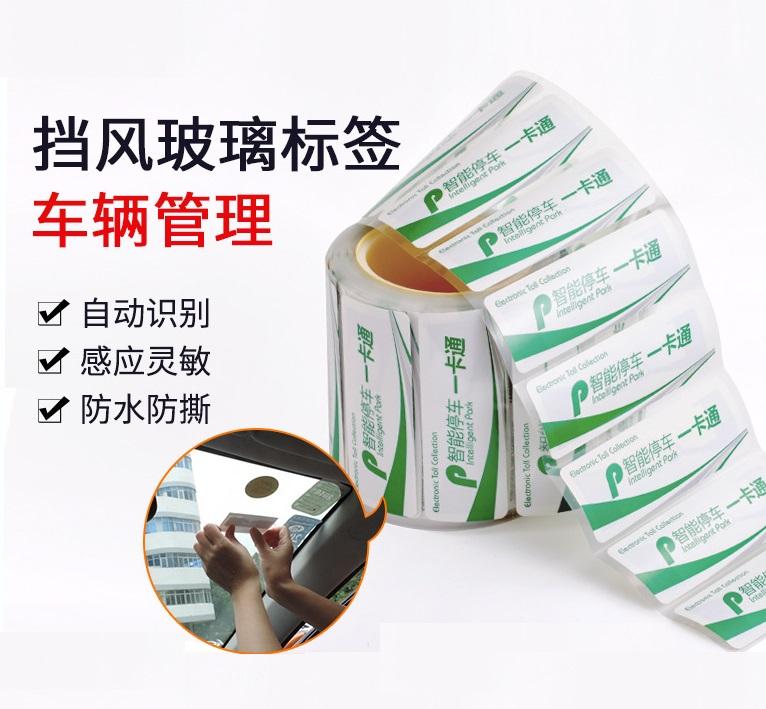

Common applications of on-metal RFID tags include asset tracking on metal containers, tools, equipment, and machinery; IT asset management (e.g., tagging servers and laptops); industrial manufacturing (e.g., tracking parts through production lines); use in the oil, gas, and mining industries where metal infrastructure dominates; and tagging returnable transport items like metal pallets and cages.

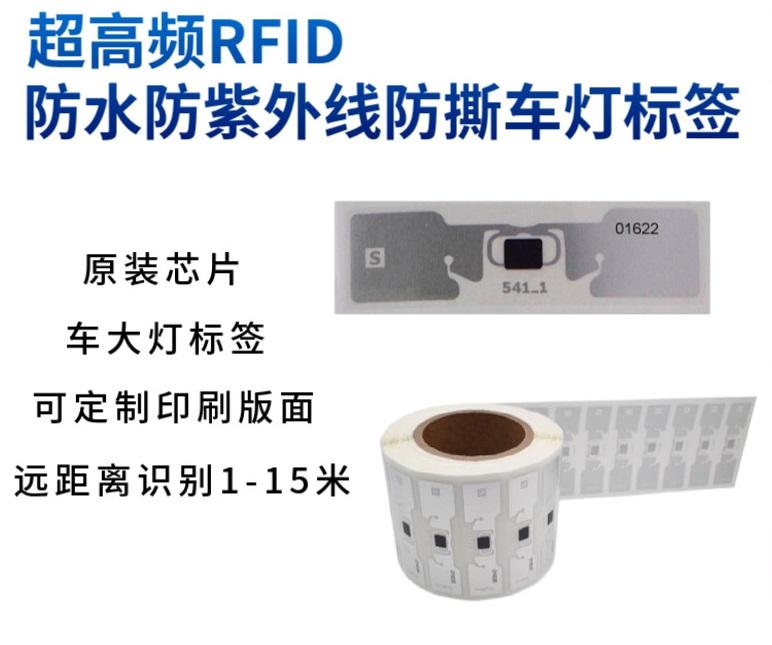

On-metal UHF RFID tags operate in the ultra-high frequency range (860–960 MHz), provide read ranges of up to 10–15 meters (depending on reader, tag size, environment), and are widely used for tracking assets, managing inventory, and monitoring equipment in metal-rich environments.

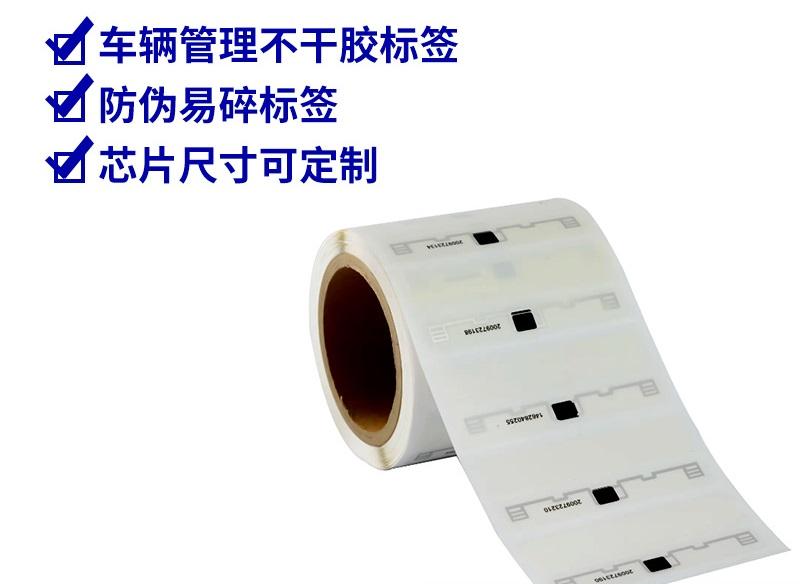

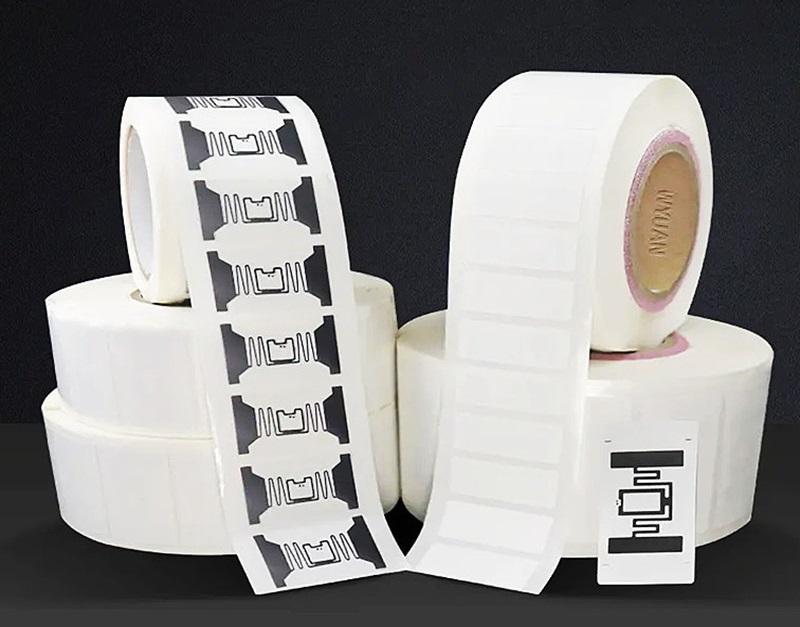

Discover our on-metal UHF RFID tags with a wide range of customization options, including chip, dimensions, printing, and EPC encoding.