RFID tags are small electronic devices that consist of a tiny chip and an antenna. They are used for various purposes, such as tracking inventory, identifying objects, and making contactless payments.

How do RFID tags work?

Overview

The way that RFID tags work always involves four steps:

Radio frequency (RF) communication

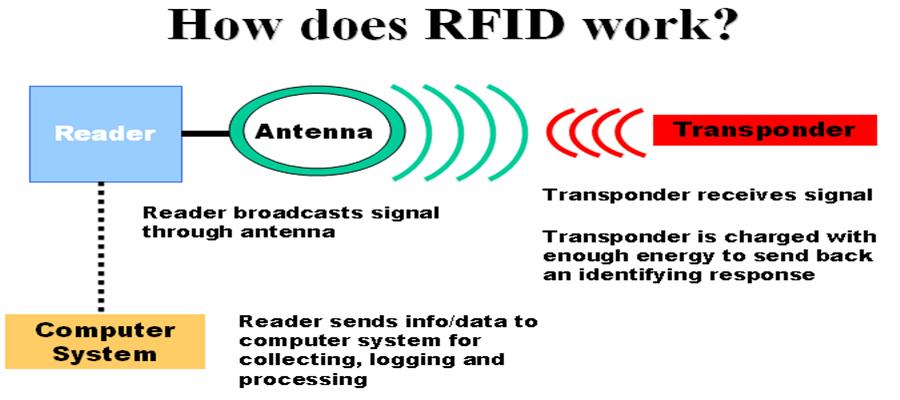

RFID tags communicate using radio waves. When an RFID reader sends out a radio signal, it energizes the RFID tag.

Powering up

There are two types of RFID tags: active and passive.

- Active RFID tags have their own power source (usually a battery) and can transmit signals over longer distances.

- Passive RFID tags don't have their own power source. Instead, they rely on the energy from the RFID reader to power up. When the reader's signal energizes the tag, the tag uses that energy to send back its stored data.

Data transmission

Once powered up, the RFID tag sends back data stored in its memory. This data can include a unique identifier for the tagged object or other information such as product details, serial numbers, or maintenance history.

Reading the data

The RFID reader captures the data sent by the tag using its antenna. The RFID reader then processes this data and can send it to a computer system for further analysis or action.

RFID Frequency Range

RFID systems operate at different frequencies depending on the application. Common frequencies include low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). Each frequency range has its advantages in terms of read range, data transfer speed, and interference resistance.

Applications of RFID tags

RFID technology finds applications in various industries, including retail, supply chain management, logistics, healthcare, and access control. For example, in retail, RFID tags can help track inventory in real-time, reducing stockouts and improving overall efficiency.

Overall, RFID tags provide a convenient and efficient way to identify and track objects without requiring direct line-of-sight or manual scanning, making them ideal for a wide range of applications.

These are some applications of RFID tags in detail:

- RFID tags for inventory management

- RFID animal tracking

- RFID vehicle tracking

- RFID tags on clothes

- RFID location tracking

- RFID and GPS tracking

How do RFID tags work in an inventory management system?

RFID tags streamline inventory management by enabling fast and accurate tracking of items without the need for direct line-of-sight scanning. RFID improves efficiency, accuracy, and transparency in inventory systems, making it a preferred choice for modern logistics and supply chain operations.

Here's how RFID tags function in an inventory management system.

Components

- RFID tags: These tags are attached to inventory items. Each tag has a microchip for storing data (e.g., product ID, batch number), and an antenna to transmit the stored data via radio waves.

- RFID readers: These readers emit radio frequency signals to power the RFID tags and read their data. They can be fixed readers that are installed at specific locations (e.g., warehouse doors), or handheld readers which are portable devices for scanning items manually.

- Inventory management software: Integrates with RFID readers to process and organize data for tracking, reporting, and analysis.

Workflow

- Tagging items: RFID tags are affixed to inventory items or their packaging. Each tag is encoded with unique data relevant to the item.

- Data transmission: RFID readers emit radio waves that activate nearby tags. And the tags respond by transmitting their stored data back to the reader.

- Data collection: The RFID reader collects the data and sends it to the inventory management system. Fixed readers might track items passing through checkpoints (e.g., warehouse entry/exit), while handheld readers are used for localized tracking.

- Real-time updates: The inventory management software updates the database in real time as items are scanned. For example, you can locate items, check stock levels, and identify missing or misplaced items.

Some common uses in inventory management

In an inventory management system, RFID tags offer speed, automation, and data-rich tracking, enabling real-time inventory updates and streamlined processes. These are some common uses of RFID tags in inventory management.

- Warehouse tracking: Monitor item movements in and out of storage.

- Stock auditing: Conduct quick and precise inventory counts.

- Supply chain visibility: Track goods throughout their journey.

- Theft prevention: Monitor unauthorized removals.

- Shelf management: Ensure timely restocking.

How is RFID technology used for animal tracking?

RFID technology is increasingly used for animal tracking, offering a range of benefits for livestock management, veterinary practices, and pet identification. This technology involves the use of RFID tags, which contain unique identification codes, enabling efficient tracking and monitoring of animals. Its ability to provide real-time data significantly improves management practices and animal welfare while facilitating compliance with regulatory requirements.

How RFID works in animal tracking

-

Tagging process

RFID tags are typically attached to the ears of animals. Each tag contains a microchip with a unique identification number that can be read by RFID readers. When an animal passes within range of a reader, the tag transmits its ID, allowing for real-time tracking and data collection on the animal's location and health status.

-

Data management

The information collected from RFID tags can include various metrics such as movement patterns, health indicators, and breeding history. This data is transmitted to a centralized database, where it can be analyzed to improve herd management practices.

Applications of RFID in animal tracking

- Livestock management: RFID is extensively used in cattle tracking to monitor health, manage breeding, and ensure compliance with regulations. Farmers can track individual animals' movements and health data in real-time, leading to better decision-making and resource allocation.

- Veterinary use: In veterinary settings, RFID tags help identify pets quickly, allowing for efficient management of medical records and owner information. When lost pets are found, veterinarians can scan their RFID tags to reunite them with their owners.

- Wildlife conservation: RFID technology is also applied in wildlife management to monitor endangered species in their natural habitats. By tagging these animals, researchers can track their movements and behaviors without invasive methods.

- Disease management: RFID plays a crucial role in tracking animal diseases by providing accurate records of animal interactions within herds. In the event of an outbreak, farmers can quickly identify affected animals and implement quarantine measures to prevent further spread.

How is RFID used in vehicle tracking?

RFID is commonly used in vehicle tracking systems for various purposes, including vehicle identification, access control, and toll collection. RFID technology plays a crucial role in modern vehicle tracking systems by providing automated solutions that enhance security, improve efficiency, and facilitate better inventory management across various applications.

Here's how RFID is used.

Types of RFID tags used

- Windshield tags: Mounted inside or outside the windshield, these tags are optimized for reading over distances greater than 20 feet and can withstand outdoor conditions.

- Rearview mirror hang tags: These are reusable tags ideal for temporary applications, allowing easy transfer between vehicles.

- Sideview mirror tags: Designed to be discreetly placed out of sight, these tags help maintain aesthetics while providing tracking capabilities.

- Active RFID tags: These tags have their own power source and can transmit signals over longer distances, making them suitable for real-time tracking across larger areas.

Applications of RFID in vehicle tracking

Vehicle identification

- RFID tags: Each vehicle is equipped with a passive or active RFID tag containing a unique identifier. These tags are usually attached to the windshield, license plate, or other parts of the vehicle.

- RFID readers: Fixed RFID readers installed at entry/exit points, checkpoints, or along routes read the tag's unique ID.

- Data collection: The system records the vehicle's passage, timestamp, and other associated details.

Access control

- Gated facilities: RFID systems are often used to automate entry and exit in parking lots, gated communities, or restricted areas. Authorized vehicles are granted access automatically when their tag is read.

- Security: Ensures that only authorized vehicles enter secure zones, minimizing unauthorized access.

Electronic toll collection

- Fast lane payments: RFID tags are commonly used in toll systems to enable vehicles to pass through without stopping. The system deducts the toll fee automatically from a prepaid account linked to the RFID tag.

- Reduced congestion: Minimizes traffic delays at toll booths.

Fleet management

- Real-time tracking: RFID readers placed strategically along a route monitor vehicles' movements, helping fleet managers track their locations.

- Operational efficiency: Data collected via RFID can optimize routes, reduce fuel costs, and ensure timely deliveries.

How does RFID work in clothing?

RFID technology is transforming the clothing industry by enhancing tracking, inventory management, and customer interaction. It improves operational efficiencies from production through retail while enhancing customer engagement and security measures. Here’s a detailed overview of how RFID works in clothing.

-

RFID tags

Each garment is equipped with an RFID tag that contains a unique identification number and can hold additional information such as size, color, and style. These tags are typically small and can be sewn into the fabric or attached to the garment label, ensuring they do not affect the aesthetic appeal of the clothing.

-

Components of RFID

An RFID system consists of three main components: RFID tag, RFID reader and the central system. The central system processes the data collected by the readers, providing real-time visibility into inventory and garment status.

-

Production process

During manufacturing, RFID tags are attached to garments. As items move through the production line, RFID readers capture data from these tags, allowing manufacturers to track inventory levels and monitor production efficiency in real-time.

-

Warehouse and distribution

Once garments are produced, they are shipped to warehouses where RFID technology is used to manage inventory. Readers scan the tags upon arrival, updating the central system with details about each item’s characteristics and stock levels. This process minimizes errors associated with manual inventory tracking.

-

Retail applications

In retail environments, RFID enhances various processes:

- Checkout efficiency: RFID allows for touchless scanning of multiple items at once, significantly speeding up the checkout process compared to traditional barcode systems.

- Inventory management: Retailers can quickly identify stock levels and locate specific items on shelves, improving restocking processes and reducing instances of overstocking or stockouts.

- Anti-theft measures: RFID tags can trigger alarms when unpaid items exit the store, providing an added layer of security against theft.

-

Consumer interaction

RFID technology creates opportunities for enhanced customer experiences through interactive displays and kiosks. Shoppers can scan garments to receive detailed information about sizes, availability, and styling recommendations.

Can RFID track location?

RFID technology is indeed capable of tracking location, and it does so through various methods and systems tailored to specific applications. RFID technology provides robust solutions for location tracking through both passive and active systems, enabling businesses to improve efficiency, reduce losses, and enhance operational visibility. Here’s an overview of how RFID can be used for location tracking.

Types of RFID systems

Passive RFID systems

These systems do not actively transmit signals and rely on readers to detect tags when they come within range. They are typically used in applications like inventory management where real-time tracking is less critical. The location accuracy is generally limited to the vicinity of the reader, usually within 20-25 feet for UHF tags.

Active RFID systems

Active RFID tags have their own power source and can transmit signals continuously. This allows for real-time tracking of assets and personnel over greater distances (up to 300 feet). Active RFID systems can provide location accuracy within 10 feet or even a few centimeters with advanced technologies like ultra-wideband (UWB).

Real-time location systems (RTLS)

RTLS employs a network of fixed readers and tags to monitor the location of objects in real time. This system can triangulate positions using multiple readers, providing precise location data on a facility map. Active RTLS can track movements continuously, making it suitable for environments like hospitals or warehouses.

Location tracking methods

-

Fixed readers

Mounted in specific locations, these readers can monitor the presence of tagged items as they pass through designated areas, such as entry and exit points in warehouses or retail spaces.

-

Handheld readers

These portable devices allow users to scan for tags manually, helping locate specific items within a defined space. This method is particularly useful in large storage areas where items are tagged and need to be located quickly.

-

Triangulation

By using multiple fixed readers, systems can determine the precise location of a tag by measuring the time it takes for signals to travel between the tag and the readers. This method enhances accuracy but may require more complex setup and calibration.

Use cases for RFID location tracking

- Inventory management: Track items in warehouses or stores.

- Asset tracking: Monitor the location of tools, equipment, or vehicles.

- Personnel tracking: Use RFID badges to check entry/exit in controlled areas.

- Event management: Monitor attendee movement or presence.

Can RFID be used for GPS tracking?

RFID and GPS are distinct technologies used for tracking assets, each with its own strengths and limitations. RFID cannot independently provide GPS functionality because it lacks satellite connectivity and does not have the necessary hardware for calculating global positions.

While RFID alone cannot be used for GPS tracking due to its inherent limitations, the two technologies can be integrated to enhance tracking solutions, which can be used for comprehensive asset management across various settings.

Differences between RFID and GPS

-

Technology basis

GPS uses a network of satellites to determine the location of a device anywhere on Earth, requiring a clear line of sight to the sky for accurate positioning. It provides real-time location data over vast distances and is suitable for outdoor tracking.

RFID operates using radio waves to communicate between tags and readers. It is primarily effective in limited areas, such as warehouses or production facilities, where RFID readers can activate tags within close range (typically up to 30 meters for passive tags).

-

Power consumption

GPS devices are power-intensive as they continuously communicate with satellites, which can lead to higher operational costs. RFID tags, especially passive ones, do not require their own power source; they draw energy from the RFID reader when in proximity. Active RFID tags have batteries but still consume less power compared to GPS devices.

-

Tracking range

GPS offers global coverage, making it ideal for tracking moving assets over long distances. RFID is limited to specific geographic areas and does not provide continuous location tracking unless within the range of a reader.

Combining RFID and GPS for enhanced tracking

RFID is not inherently designed for GPS tracking, but it can be integrated into systems that support location tracking in certain scenarios. Integrating RFID with GPS can create a comprehensive tracking system that leverages the strengths of both technologies. Here's how it works:

- RFID tags are attached to assets to identify them uniquely.

- A GPS-enabled device (e.g., a tracker or vehicle) reads the RFID tag, determining which asset is in its vicinity.

- The GPS device transmits the location of the RFID-tagged item to a central system.

Applications of combined RFID and GPS

- Fleet management: Identify cargo or equipment with RFID tags, while GPS tracks the vehicle carrying them.

- Supply chain and logistics: Monitor tagged goods in transit; GPS tracks the vehicle, and RFID ensures item-level identification.

- Security systems: RFID verifies the presence of tagged items or people, while GPS records their real-time location.