This article discusses the different frequencies and ranges of RFID technology, including Low Frequency (LF), High Frequency (HF), and Ultra-High Frequency (UHF) RFID.

RFID range and different frequencies

RFID systems operate at different frequency bands, each with its own typical read range capabilities. Low Frequency (LF) RFID has a read range of around 10 cm, while High Frequency (HF) RFID has a read range of 3 MHz to 30 MHz, and Ultra-High Frequency (UHF) RFID has a read range of up to 6 meters.

The read range is influenced by factors such as frequency, antenna design, environmental conditions, and system configuration. LF RFID has the shortest read range but is less susceptible to interference, HF offers a moderate read range and is less affected by interference than UHF, and UHF RFID provides the longest potential read range but is more sensitive to interference from metals and liquids.

Low Frequency (LF) RFID

Low Frequency (LF) RFID systems operate in the 30 KHz to 300 KHz frequency range, with common frequencies being 125 KHz and 134 KHz. They have a short read range of 10 cm, slow read speed, and resistance to interference from metals and liquids. They are commonly used for access control, animal tracking, asset tracking, automotive immobilizers, and point-of-sale applications.

Despite their limited read range, LF RFID's ability to penetrate thin metal surfaces and operate in moist environments makes it suitable for specific applications requiring close proximity reading with high reliability.

High Frequency (HF) RFID

High Frequency (HF) RFID systems typically operate at 13.56 MHz frequency.

They offer a balance between read range and interference resistance, making them suitable for applications where the RFID tags need to be read at moderate distances and in environments with some presence of metals or liquids. They are relatively insensitive to humidity and water compared to UHF RFID.

HF RFID systems have the following key characteristics:

- High Frequency RFID (HF) has a read range of 10 cm to 1 meter, with some specialized readers reaching up to 30 cm.

- The data transfer rate ranges from medium to high, making it ideal for swiftly transferring large volumes of data.

- Moderately affected by interference from metals and liquids compared to UHF RFID.

- Commonly used for ticketing, payments, data transfer, object traceability, and guided applications where tags pass through readers in a consistent position.

- ISO 15693 for object traceability, ISO/IEC 14443 for smart cards and payments (MIFARE), ISO/IEC 18092 for Near Field Communication (NFC).

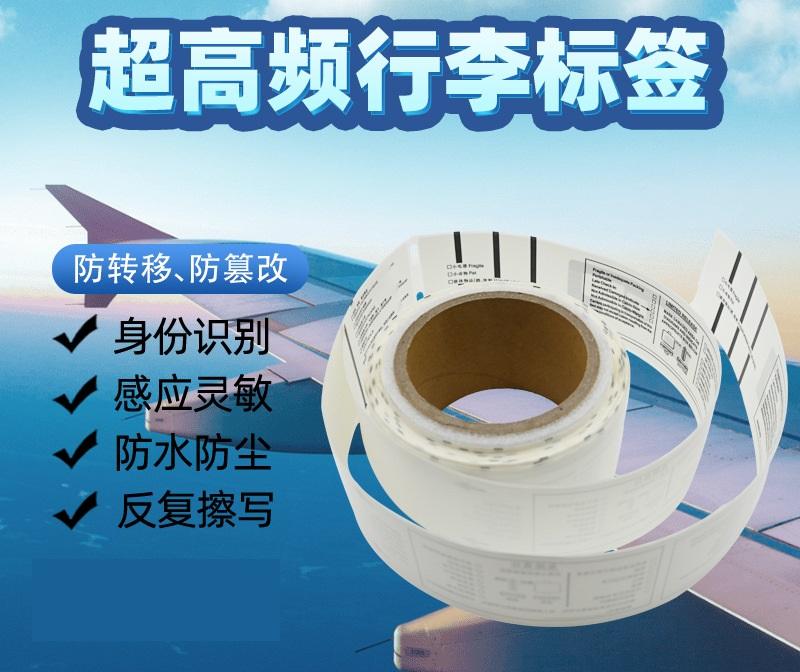

Ultra-High Frequency (UHF) RFID

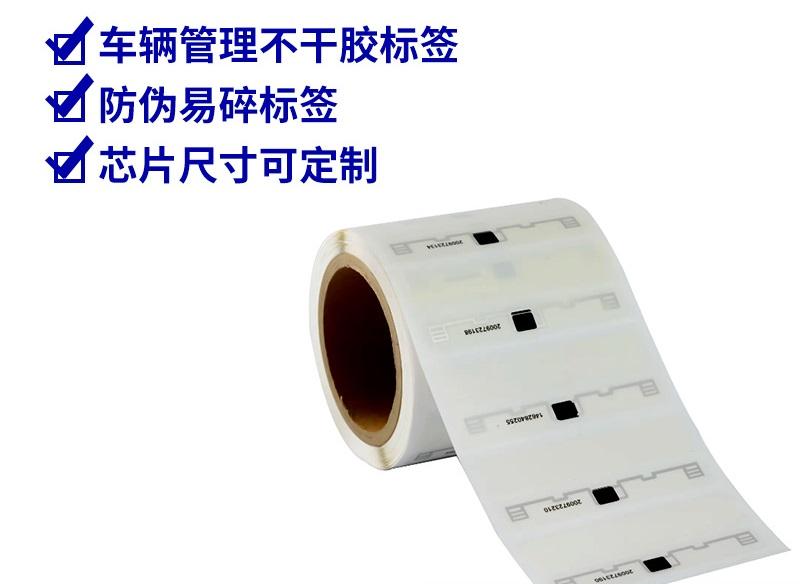

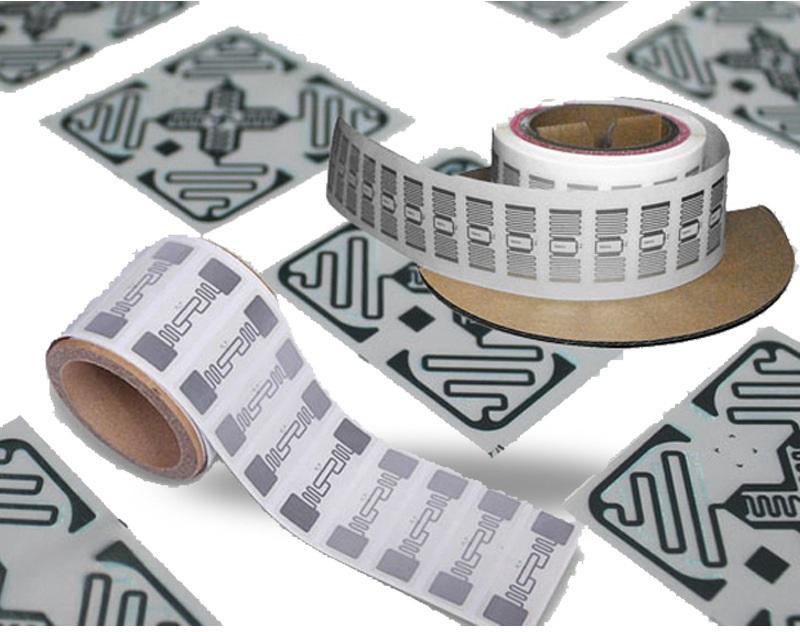

Ultra-High Frequency (UHF) RFID systems operate in the 860 MHz to 960 MHz frequency range, offering long read ranges up to 12 meters and high data transfer rates for applications requiring multiple tags simultaneously.

UHF signals are more susceptible to interference from metals, liquids, and other materials compared to lower frequencies. They comply with the EPC Global Gen2 (ISO 18000-63) standard, enabling worldwide deployment.

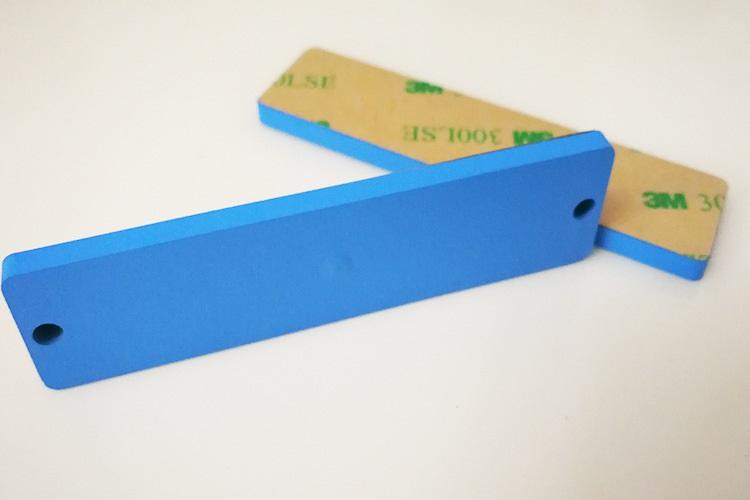

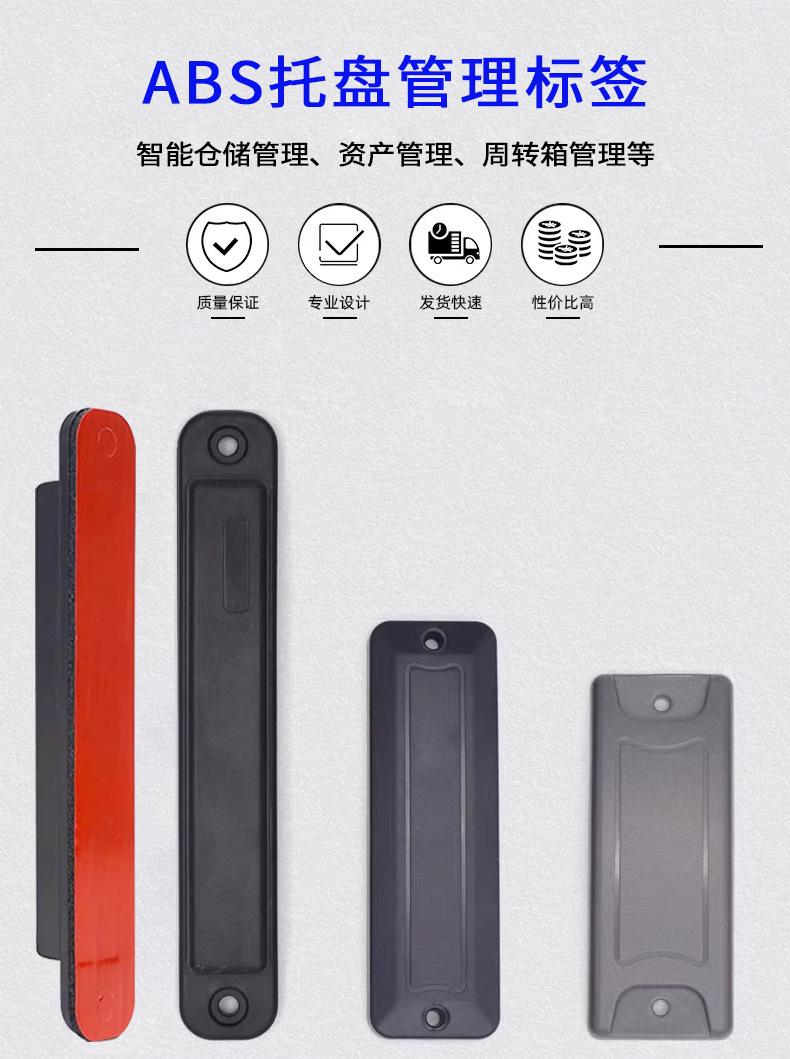

UHF RFID is widely used in supply chain management, inventory tracking, asset management, access control, and electronic toll collection systems. They are cost-effective, as they are generally less expensive to manufacture compared to LF and HF tags. However, interference from materials like metals and liquids can affect UHF RFID's performance. Advancements in tag, antenna, and reader design have improved UHF RFID's ability to operate in challenging environments.

What are the advantages of using UHF RFID over other types of RFID

Ultra-High Frequency (UHF) RFID offers several advantages over other types of RFID, including longer read ranges, high data transfer rate, lower costs, and global standards. UHF RFID systems can read multiple tags simultaneously at high speeds, enabling high-throughput operations and faster product identification and tracking. They are generally more cost-effective than Low Frequency (LF) and High Frequency (HF) tags, making them suitable for large-scale tagging without high costs. UHF RFID also complies with the EPC Global Gen2 (ISO 18000-63) standard, enabling worldwide deployment and interoperability.

However, UHF RFID is more susceptible to interference from metals, liquids, and electromagnetic signals compared to Low Frequency (LF) and High Frequency (HF) frequencies. Advancements in tag, antenna, and reader design have improved UHF RFID's performance in challenging environments. Overall, UHF RFID offers advantages such as longer read ranges, faster data rates, lower costs for large deployments, and global standards, making it a preferred choice for applications requiring long-distance, high-throughput tracking and supply chain visibility.

What are some examples of industries that use UHF RFID

The long read range, high data transfer rate, and global standards compliance of UHF RFID make it suitable for industries that require tracking and managing valuable assets, inventory, and supply chain operations over longer distances.

These are some key industries that utilize Ultra-High Frequency (UHF) RFID technology.

Aerospace Industry

The aerospace industry has been one of the pioneers in adopting UHF RFID technology. Major companies like Airbus, Boeing, and Embraer have implemented UHF RFID for tracking aircraft parts, maintenance records, and supply chain management.

Retail Industry

The retail industry, particularly apparel retail, is the largest adopter of UHF RFID technology. Around 64% of the UHF RFID market share by tag volume and 72% by market value is driven by the retail apparel sector for applications like inventory management and supply chain tracking.

Supply Chain and Logistics

The supply chain and logistics industry accounts for 22% of the UHF RFID market share by tag volume and 14% by market value. UHF RFID is used for tracking and managing inventory, assets, and shipments across the supply chain.

Manufacturing

UHF RFID is increasingly being adopted in the manufacturing sector for applications such as work-in-progress tracking, asset management, and supply chain visibility.

Warehousing and Distribution

UHF RFID technology is utilized in warehouses and distribution centers for locating and tracking items quickly, improving inventory accuracy and efficiency.