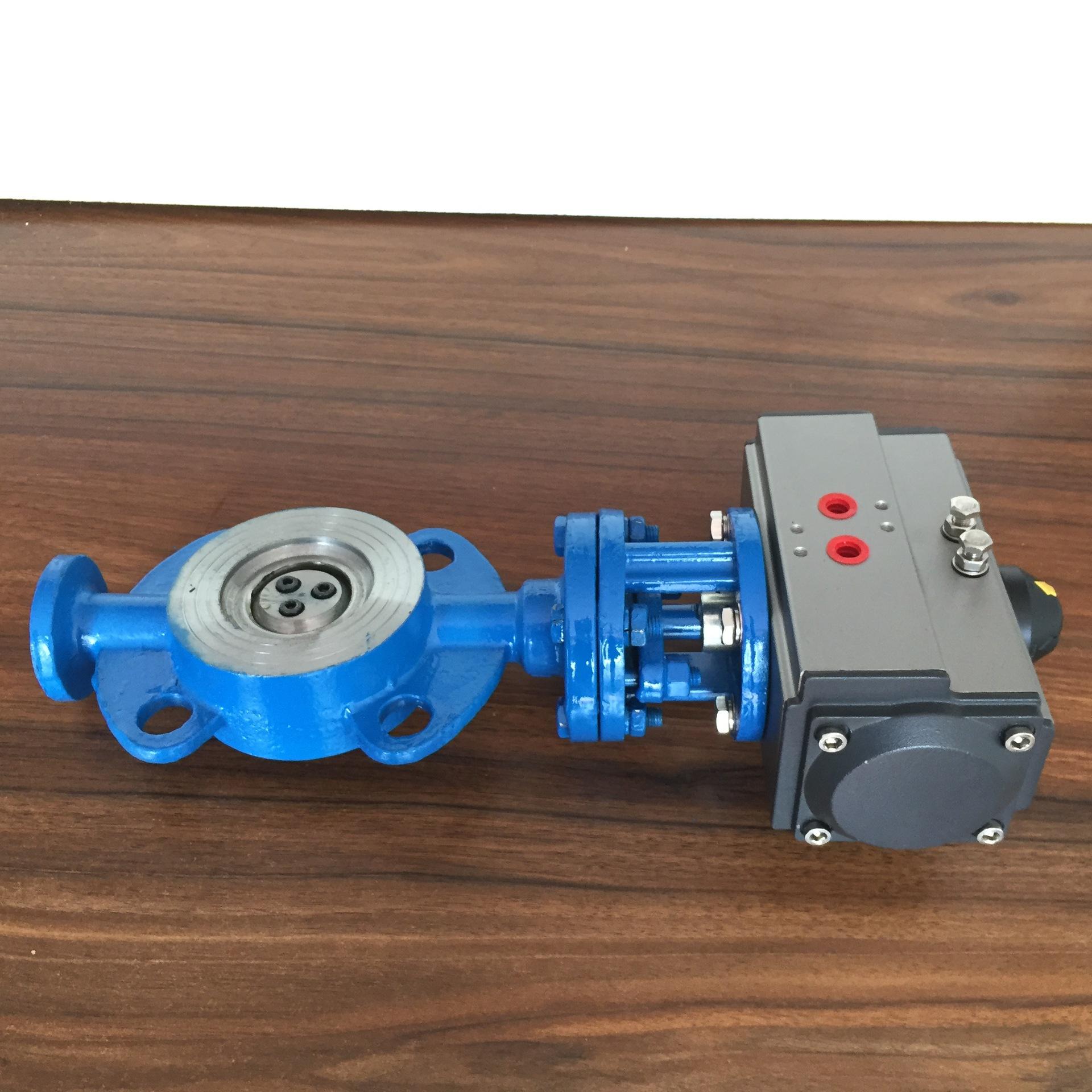

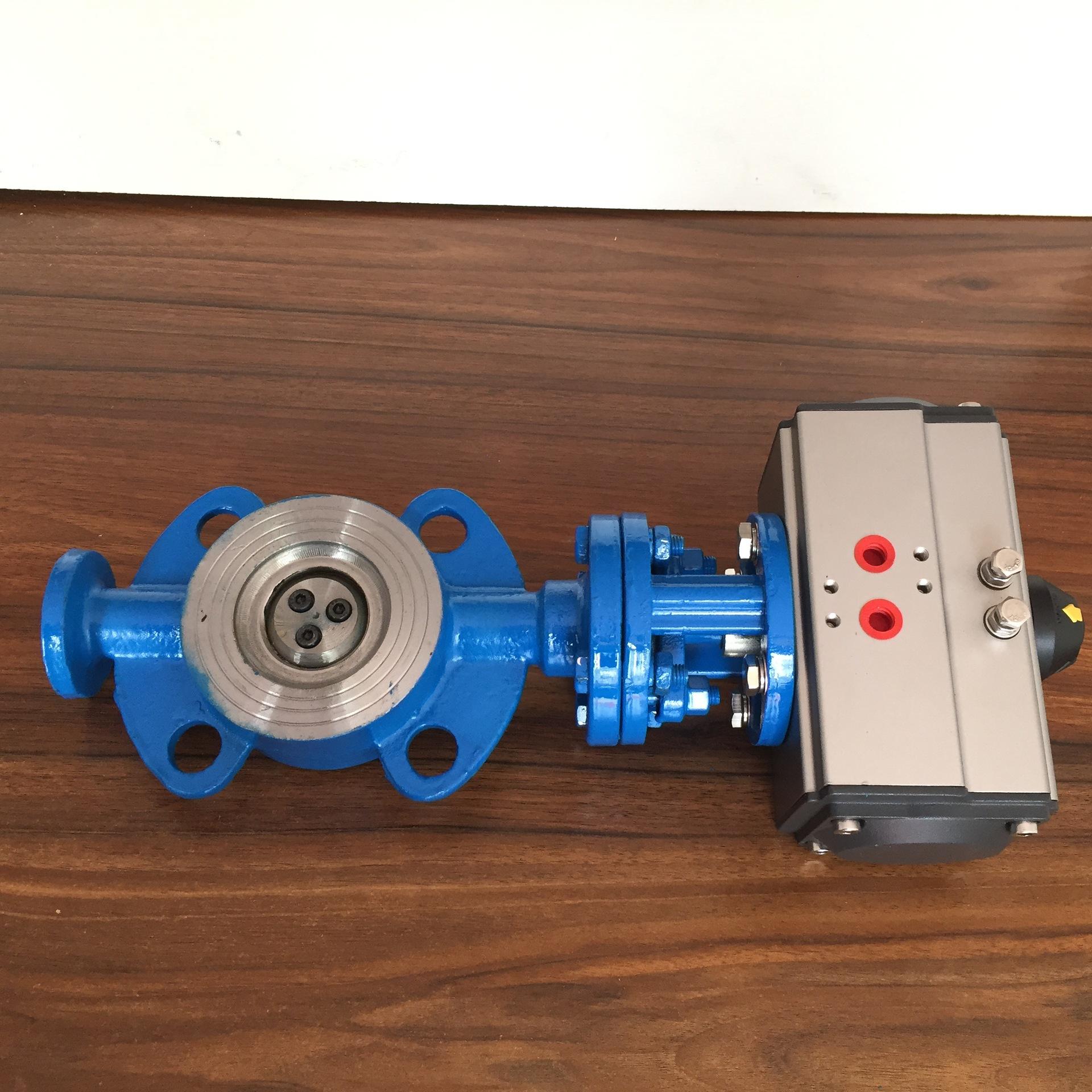

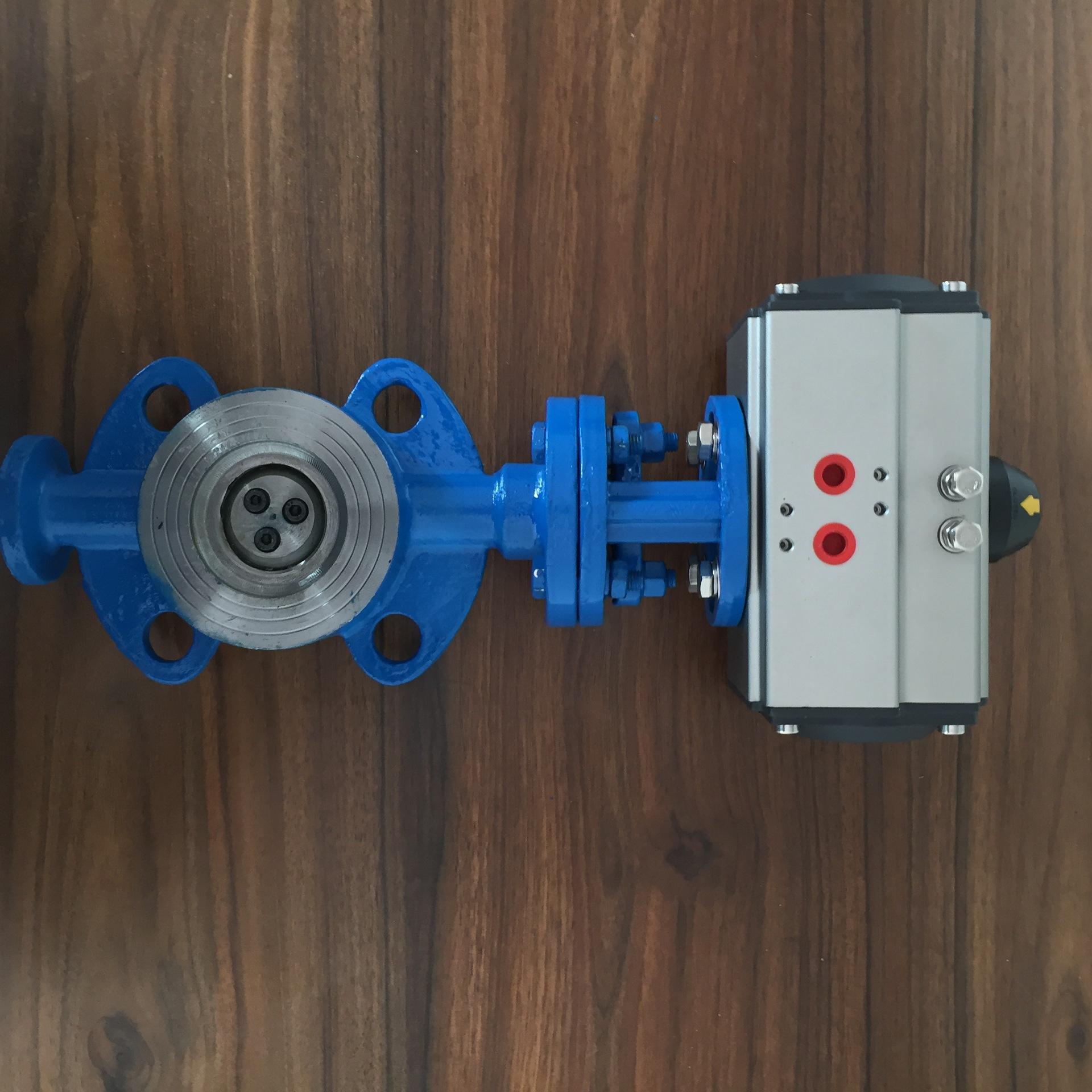

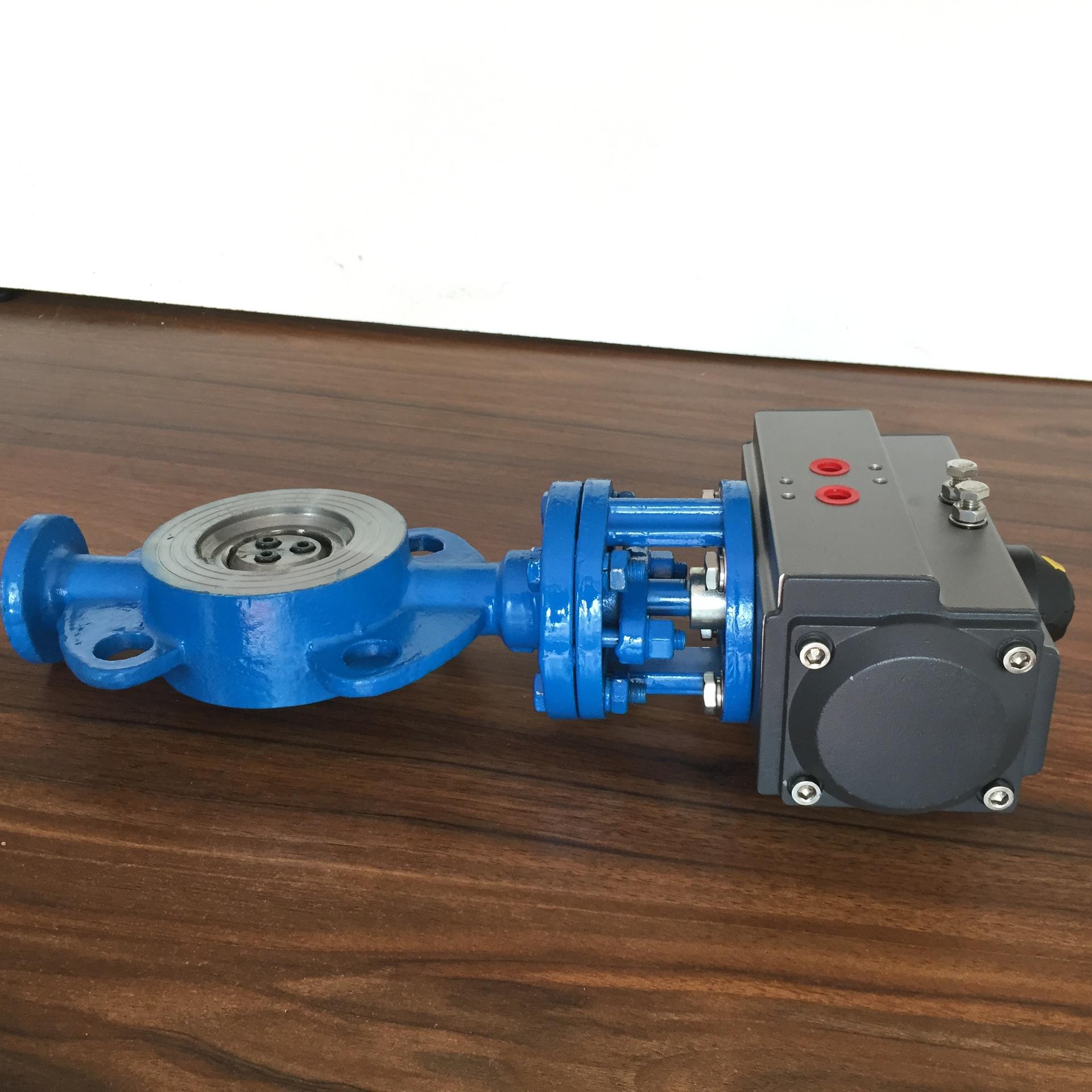

Triple Offset Butterfly Valves

A triple offset butterfly valve is a type of butterfly valve designed with three offsets to eliminate friction between the disc and the seat during operation, resulting in a tight, bubble-tight seal. The first two offsets position the shaft and disc away from the seat, while the third offset angles the sealing surfaces for enhanced durability and reduced wear. This design allows the valve to handle high pressure, high temperature, and corrosive media with minimal leakage. Triple offset butterfly valves are commonly used in industries such as oil and gas, power generation, and chemical processing due to their superior sealing performance, long service life, and low maintenance requirements.

Showing 99 results

(23)

$

70.33

3–10 day delivery

Ships worldwide

(26)

$

39.87

3–10 day delivery

Ships worldwide

(63)

$

120.88

3–10 day delivery

Ships worldwide

(28)

$

713.33

3–10 day delivery

Ships worldwide

(26)

$

55.81

3–10 day delivery

Ships worldwide

(62)

$

169.23

3–10 day delivery

Ships worldwide

(97)

$

770.32

3–10 day delivery

Ships worldwide

(19)

$

170.33

3–10 day delivery

Ships worldwide

(47)

$

448.22

3–10 day delivery

Ships worldwide

(45)

$

317.63

3–10 day delivery

Ships worldwide

(60)

$

1293.12

3–10 day delivery

Ships worldwide

(34)

$

75.88

3–10 day delivery

Ships worldwide

(56)

$

1466.58

3–10 day delivery

Ships worldwide

(57)

$

51.49

3–10 day delivery

Ships worldwide

(63)

$

39.66

5–10 day delivery

Ships worldwide

(8)

$

51.68

5–10 day delivery

Ships worldwide

(91)

$

124.22

5–10 day delivery

Ships worldwide

(99)

$

171.94

5–10 day delivery

Ships worldwide

(6)

$

213.28

5–10 day delivery

Ships worldwide

(28)

$

120.88

3–10 day delivery

Ships worldwide