Valves exist everywhere—homes, factories, HVAC systems, irrigation systems, water heaters, chemical lines, and more. Yet many people still struggle with the simplest question: Is the valve open or closed?

This guide explains how to tell whether a valve is open or closed, what determines the valve’s position, and how to make absolutely sure a water valve is fully closed. This guide includes step-by-step explanations, visual-style descriptions, comparison tables, and practical instructions.

How to tell if a valve is open or closed?

Determining a valve’s position largely depends on its design. While all valves control fluid flow, different models indicate "open" and "closed" in different ways. Here are the most common methods you can use:

1. Look at the handle orientation (most common rule)

For most manual valves, the handle direction tells you everything:

| Handle Direction | Status | Meaning |

|---|---|---|

| Parallel to the pipe | Open | Flow path aligned; water/gas can pass |

| Perpendicular to the pipe | Closed | Flow path blocked |

This applies especially to ball valves and most quarter-turn valves.

2. Check the stem position

Some valves have a stem that moves when operated:

- Stem rises when opened → open

- Stem lowers when closed → closed

This is common on gate valves.

3. Look for visual indicators

Many industrial valves include:

- Arrows showing "open" or "closed"

- Position windows

- Mechanical indicators attached to actuators

4. Feel for resistance

When operating or closing a valve:

- Loose turning → probably still mid-position

- Sudden stop → reached full closed position

5. Check flow (if safe)

For non-dangerous systems like home water lines:

- Open a faucet downstream.

- If no water flows → the valve is closed.

- If water flows → the valve is open.

Safety note: This should never be done on hazardous chemical, gas, steam, or high-pressure systems. For those, use proper instruments (pressure gauges, leak detectors) or consult qualified personnel.

What determines whether a valve is open or closed?

What makes a valve "open" or "closed" is not only the handle but the internal mechanism. Each valve type works differently.

1. Mechanical design

Every valve has an internal obstruction (ball, gate, disc, plug, diaphragm) that moves to allow or stop flow.

| Valve Type | Internal Mechanism | How It Determines Open/Closed |

|---|---|---|

| Ball valve | Rotating drilled ball | Hole aligned with flow = open |

| Gate valve | Vertical gate lifts/lowers | Gate fully raised = open |

| Globe valve | Disc presses into seat | Disc lifted = open |

| Butterfly valve | Rotating disc | Disc parallel = open |

| Plug valve | Rotating plug with passage | Passage aligned = open |

2. Handle type

Different valves use different handle mechanisms that influence how open/closed positions are indicated:

- Quarter-turn handles (ball, butterfly, plug)

- Multi-turn handles (gate, globe)

- Levers

- Wheels

- Knobs

These differences affect how many rotations are needed and how clearly the position is shown.

3. Internal stops

Valves often include mechanical "stops" to prevent improper movement:

- Open stop — prevents the valve from over-opening

- Closed stop — prevents over-tightening and seat damage

These stops ensure the internal mechanism aligns properly and protects the valve components.

4. Actuator logic (for automated valves)

Industrial valves may use:

- Electric actuators

- Pneumatic actuators

- Hydraulic actuators

These systems use limit switches or position sensors to define "open" and "closed".

How to make sure a water valve is closed?

Ensuring a water valve is truly closed is important for:

- Preventing leaks

- Maintaining safety during repairs

- Avoiding flooding or property damage

You can confirm closure using these steps:

-

Turn the valve fully until it stops

- For a ball valve: Turn the lever 90° until perpendicular.

- For a gate/globe valve: Rotate the wheel clockwise until it no longer turns.

-

Check downstream water flow

Open a faucet downstream:

- If no water comes out, the valve is fully closed.

- If water slows but does not stop, the valve is partially stuck or damaged.

-

Check the handle orientation

Perpendicular = closed (for quarter-turn valves)

-

Check the stem

Stem fully down (gate valve) = closed.

-

Listen

Put your ear close:

- Hissing or water movement noise = still open or partially open.

- Silence = closed.

-

For major supply valves (water main)

Use a pressure test:

- Shut the valve

- Open a faucet

- Wait

- If pressure drops to zero → valve is closed

- If pressure remains → valve is leaking internally

Types of valves and how to identify open vs. closed

Different valves show open/closed positions differently. Here’s how to identify each type.

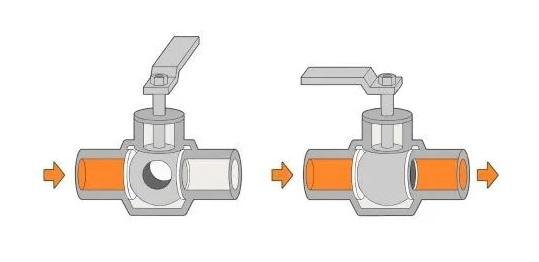

Ball valve: how to tell if it is open or closed

Ball valves are the easiest to read.

How ball valves work

Inside is a metal ball with a hole drilled through the center.

- Hole aligned with pipe → open

- Hole rotated 90° → closed

How to check

| Handle Position | Meaning |

|---|---|

| Parallel to pipe | Open |

| Perpendicular to pipe | Closed |

Why it matters

Ball valves seal tightly and are common in:

- Residential water supply

- Gas lines

- Irrigation systems

- HVAC systems

Gate valve: how to tell open vs. closed

Gate valves use a rising or non-rising stem design.

Rising stem type

This is easiest to read:

- Stem rises visibly as valve opens

- Stem lowers into body when closed

Non-rising stem

The stem does not rise. To check:

- Count turns: fully clockwise until it stops = closed

- Resistance test: closed position has a firm stop

Common mistakes

People often over-tighten gate valves, damaging the seat. A gate valve should be:

- Fully open

- Or fully closed

- Never half-open for throttling.

Globe valve: how to tell its position

Globe valves regulate flow more smoothly than gate valves.

How to identify open vs. closed

- Turn the handle counterclockwise to open

- Clockwise to close

- You will feel increased resistance at full close

Unlike gate valves, globe valves:

- Can be partially open for throttling

- Do not have rising stems on many models

Visual indicator

Some have a small indicator screw or hash marks showing position.

Butterfly valve: how to tell if it is open or closed

A butterfly valve has a rotating disc inside.

How to check:

| Handle Direction | Position |

|---|---|

| Parallel | Open |

| Perpendicular | Closed |

Butterfly valves may have:

- Position plates

- Notched handles

- Mechanical indicators

These show exact angle (0°, 30°, 60°, 90°).

Plug valve: reading open vs. closed

Plug valves operate similar to ball valves.

How to check:

- Lever parallel = open

- Lever perpendicular = closed

Some industrial models also include:

- Indicator arrows

- Casting marks showing flow path

Symptoms of a valve that looks closed but is actually still open

Sometimes the handle says "closed", but water still flows. Causes include:

-

Internal damage

Corrosion, mineral buildup, or wear may prevent full closure. -

Broken stem

The handle turns but internal parts don’t move. -

Seat damage

Even if "closed", water leaks through. -

Gate valves stuck open

The gate may detach from the stem. -

Incorrect installation

Valve installed backwards (for directional valves).

Common mistakes when checking valve status

These errors cause confusion or damage.

-

Mistake 1: Thinking all valves use the same rule

Not all valves use the "parallel = open" rule. -

Mistake 2: Over-tightening

Turning a valve too hard can destroy internal seals. -

Mistake 3: Confusing multi-turn valves with quarter-turn valves

A multi-turn valve can take 5–12 turns to close. -

Mistake 4: Partial closure

Valves may seem closed but actually be half-open. -

Mistake 5: Checking with unsafe methods

Never test gas valves by opening downstream lines.

How to make sure a valve is open

Sometimes the question is the opposite: Is the valve fully open?

Check these points:

- Handle parallel to pipe (for quarter-turn valves).

- Wheel fully counterclockwise (for gate/globe valves).

- Full flow from downstream fixtures.

- No sound of restriction or water hammer.

- Stem fully raised (for rising stem valves).

How to check valve position in industrial systems

Industrial valves require more formal checks.

-

Position indicators

Many valves include:

- Mechanical flags

- LED indicators

- Electronic switches

-

Control panel signals

Automated valves link to:

- SCADA systems

- PLC controllers

- Building automation systems

These indicate:

- Open

- Closed

- Intermediate position

- Fault

-

Valve travel sensors

Linear or rotary sensors measure:

- 0% (closed)

- 50% (half-open)

- 100% (open)

-

Lockout/tagout (LOTO)

Industrial safety requires locking valves in known positions.

Troubleshooting a valve that won’t open or close

If a valve gets stuck:

Problem: Hard to turn

Causes:

- Limescale

- Corrosion

- Lack of lubrication

- Aging seals

Solutions:

- Apply penetrating oil

- Gently work back and forth

- Do not use extreme force

Problem: Turns freely but does nothing

Likely causes:

- Broken stem

- Detached handle

- Gate/plug separated

Needs repair or replacement.

Problem: Leaks even when closed

Causes:

- Damaged seat

- Worn gasket

- Debris inside valve

May require flushing or replacing seals.

Quick comparison of how to tell if different valves are open or closed

| Valve Type | Open Position | Closed Position | Easiest Way to Identify |

|---|---|---|---|

| Ball valve | Handle parallel | Handle perpendicular | Look at handle orientation |

| Gate valve | Stem fully raised | Stem fully lowered | Stem height or full turn stop |

| Globe valve | Turns counterclockwise | Turns clockwise | Feel resistance at closed |

| Butterfly valve | Disc parallel | Disc perpendicular | Lever alignment |

| Plug valve | Lever parallel | Lever perpendicular | Handle orientation |

| Diaphragm valve | Handle counterclockwise | Clockwise | Indicator or flow test |

Safety tips when checking valve status

-

Avoid forcing a valve

Excess force may break internal components. -

Never check gas valves by flow tests

Always use:- Leak detectors

- Manometers

- Soapy water for bubbles

-

Wear gloves for hot water valves

Pipes may be extremely hot. -

Shut off main water before repairs

Avoid burst pipes or flooding. -

Label important valves

Especially for:- Water main

- Gas line

- Heater

- Irrigation

Conclusion

Identifying whether a valve is open or closed isn’t difficult once you know what to look for. Whether you’re handling a simple home water supply valve or a complex industrial valve with actuators, understanding the mechanics behind each design helps you inspect, maintain, and troubleshoot valve systems safely.

This article’s methods—checking handle orientation, stem height, flow, resistance, and indicators—will help you confidently determine valve position in almost any scenario.