This article provides a comprehensive overview of butterfly valves, exploring their design, operation, applications, and maintenance practices for industrial and residential systems.

What is a butterfly valve

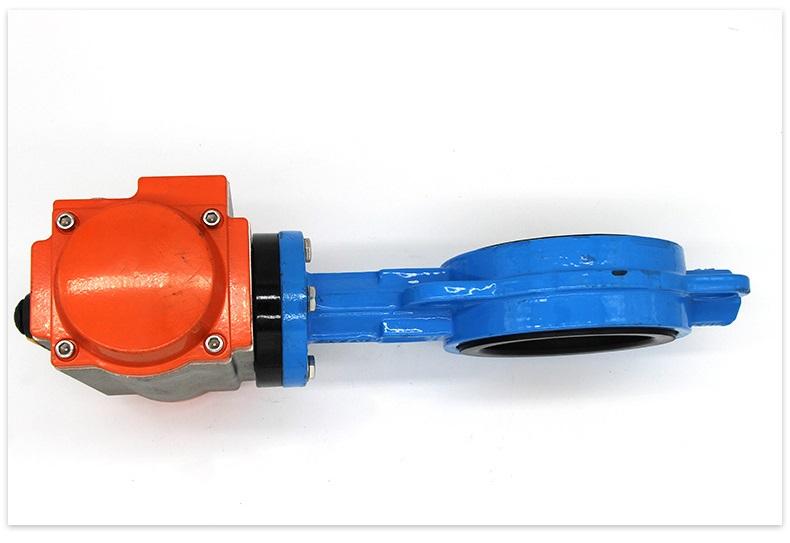

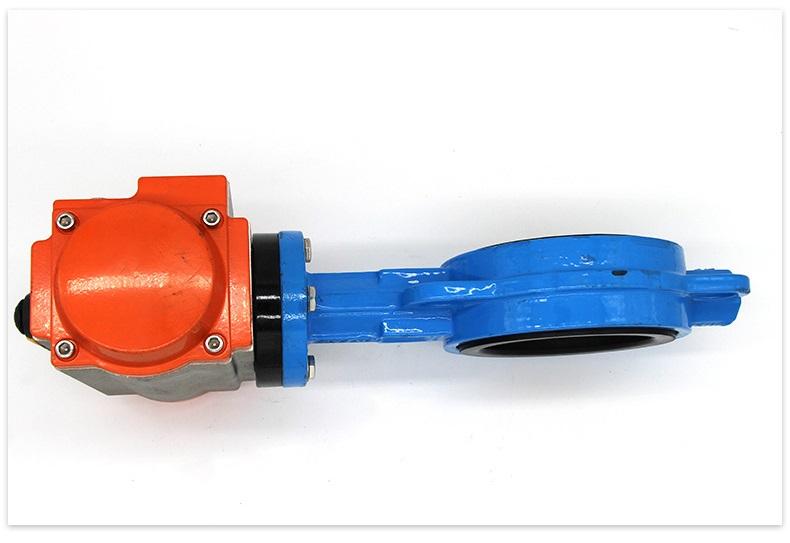

A butterfly valve is a type of quarter-turn valve used to regulate the flow of fluids through a pipe. Its defining feature is a flat, circular disc (the "butterfly") mounted on a rotating shaft that, when turned, opens or closes the valve. These valves are compact, lightweight, and cost-effective, making them popular across industries that require efficient fluid control.

Key components of a butterfly valve include:

- Valve body: The main housing that holds the internal components and provides connection points to the piping system.

- Disc: The flat, circular component that rotates to regulate fluid flow.

- Shaft: Connects the actuator or handle to the disc and allows rotation.

- Seat: Provides a sealing surface between the disc and valve body to prevent leakage.

- Actuator/Handle: Allows manual or automated control of the valve position.

Butterfly valves can be categorized into several types, including concentric (or "wafer"), double-offset, and triple-offset, each suited to specific operational requirements and pressure ratings.

How does a butterfly valve work?

The butterfly valve operates using a simple rotational mechanism. By turning the disc 90 degrees, the valve moves between fully open and fully closed positions. The disc’s orientation to the flow path determines the valve's operational state:

- Fully open: The disc aligns with the pipe, offering minimal obstruction to flow.

- Partially open: The disc is angled, allowing flow regulation or throttling.

- Fully closed: The disc is perpendicular to the pipe, creating a seal and stopping flow.

The valve can be controlled manually with a lever, gear, or automatically via pneumatic, hydraulic, or electric actuators. This flexibility makes butterfly valves suitable for diverse applications.

What is the most common application for a butterfly valve?

Butterfly valves are widely used across industries due to their simplicity, cost-effectiveness, and reliable operation. Their most common applications include:

- Water treatment and distribution: Butterfly valves regulate flow in municipal water systems, wastewater treatment, and irrigation.

- HVAC systems: They control airflow and water flow in heating, ventilation, and air conditioning networks.

- Chemical and process industries: Resistant materials allow the handling of corrosive chemicals in industrial pipelines.

- Food and beverage industry: Sanitary butterfly valves with stainless steel and hygienic seals are ideal for food-grade liquids.

- Power plants: Cooling water systems, gas pipelines, and steam distribution often rely on butterfly valves for flow control.

Their ability to handle large volumes at moderate pressures makes them particularly favored for water and chemical applications, where full shut-off is not always necessary but flow regulation is critical.

How to properly install a butterfly valve?

Correct installation is crucial for the reliable operation and longevity of a butterfly valve. Here’s a step-by-step guide:

- Preparation: Inspect the valve, check for damage, and verify compatibility with the pipeline size and pressure rating.

- Orientation: Ensure the valve is installed with the disc in the partially open position to avoid damage during tightening.

- Alignment: Align the valve with the pipeline. Avoid forcing the valve into position as misalignment can damage the seat or cause leaks.

- Gasket/Seal Placement: Install any required gaskets or seals correctly between the valve and flanges to ensure tight sealing.

- Bolting: Tighten flange bolts gradually in a crisscross pattern to evenly distribute pressure and avoid distorting the valve body.

- Actuator or Handle Installation: Attach the actuator, lever, or gearbox according to the manufacturer’s instructions.

- Testing: Conduct a pressure or leak test before full operation. Slowly open and close the valve to verify smooth movement.

Proper installation reduces maintenance needs and ensures the valve operates efficiently without premature wear.

How to tell if a butterfly valve is open?

Determining the position of a butterfly valve is straightforward due to its quarter-turn operation:

- Visual inspection: Most valves have a lever or handle that aligns with the pipeline direction when fully open.

- Disc orientation: The disc inside the valve is parallel to the pipe in the open position, and perpendicular when closed.

- Indicator: Many modern valves feature position indicators or digital sensors that display open, closed, or partially open states.

Checking valve position regularly is important in critical systems to ensure proper flow control and safety compliance.

Is a butterfly valve a shut-off valve?

Yes, a butterfly valve can act as a shut-off valve, but it is primarily designed for flow regulation. When fully closed, the disc presses against the valve seat, stopping flow entirely. However, compared to globe or gate valves, butterfly valves may have a small amount of leakage in certain designs, especially under high-pressure conditions. For applications requiring absolute zero leakage, high-performance or triple-offset butterfly valves are recommended.

Are butterfly valves prone to leaking?

Butterfly valves are generally reliable, but their sealing performance depends on design, materials, and installation:

- Concentric (wafer) valves: May develop minor leaks over time due to seat compression or wear.

- Double-offset valves: Offset design reduces seat wear and improves sealing for higher pressure and temperature applications.

- Triple-offset valves: Designed for high-performance applications with virtually zero leakage, suitable for critical services like gas pipelines and chemical processes.

Regular inspection, proper installation, and maintenance are essential to minimize leakage risks and maintain reliable operation.

Are butterfly valves used for gas?

Yes, butterfly valves are frequently used for gas applications, particularly in low- to medium-pressure systems. High-performance, double- or triple-offset butterfly valves are preferred in gas service because they provide tight sealing, durability, and fast actuation. Industries using butterfly valves for gas include:

- Natural gas distribution networks

- Industrial gas pipelines

- Oil and gas processing plants

- Power generation facilities using fuel gases

Material selection is critical in gas applications, with stainless steel, carbon steel, and specialized elastomers being common for valve bodies and seats.

What is the life expectancy of a butterfly valve?

The lifespan of a butterfly valve depends on several factors, including design, materials, operational conditions, and maintenance. Typical ranges include:

- Standard wafer or lug-style valves: 5–15 years in moderate conditions.

- Double-offset valves: 10–20 years when properly maintained and used under recommended pressures and temperatures.

- Triple-offset valves: 20–30+ years, particularly in high-pressure, high-temperature, or corrosive environments.

Regular maintenance, including cleaning, lubrication, and periodic inspection of seals and discs, significantly extends valve life and ensures reliable performance.

Types of butterfly valves

Butterfly valves can be classified by their construction and operational characteristics:

- Wafer-style: Fits between two flanges, lightweight, and cost-effective, commonly used in water treatment and HVAC systems.

- Lug-style: Bolted independently to each flange, allows for one-side removal of piping without dismantling the entire system.

- Double-offset: Features an offset disc and shaft design that reduces friction and improves sealing, suitable for medium- to high-pressure systems.

- Triple-offset: Provides zero-leakage performance for critical applications, with the seat and disc offset in three planes to prevent wear.

- High-performance butterfly valves: Made for demanding conditions, such as high temperature, corrosive fluids, or gas pipelines.

How to maintain a butterfly valve

Proper maintenance is essential for long-term performance of butterfly valves. Maintenance tasks include:

- Periodic inspection: Check for leaks, corrosion, or wear on the disc, seat, and shaft.

- Lubrication: Apply appropriate lubricants to the shaft and moving components if recommended by the manufacturer.

- Cleaning: Remove sediment or debris that may hinder valve operation, particularly in water or chemical systems.

- Seal replacement: Replace worn or damaged seals promptly to maintain tight closure.

- Functional testing: Operate the valve through its full range to ensure smooth movement and proper sealing.

How to properly select a butterfly valve

Selecting the right butterfly valve for your application requires considering several key factors:

- Fluid type: Water, gas, oil, chemicals, or slurry may dictate material and seat selection.

- Pressure rating: Ensure the valve can withstand the system’s maximum operating pressure.

- Temperature rating: Verify compatibility with system temperature extremes.

- Valve size: Select a size that fits your piping while providing appropriate flow capacity.

- Actuation method: Decide between manual, electric, pneumatic, or hydraulic operation.

- Industry standards: Consider compliance with ANSI, API, ISO, or other relevant standards.

Careful selection reduces maintenance costs, prevents leaks, and ensures reliable flow control for the valve’s lifespan.

Conclusion

Butterfly valves are versatile, efficient, and widely used in industries ranging from water treatment and HVAC systems to chemical processing and gas pipelines. Their simple quarter-turn operation, compact design, and cost-effectiveness make them a preferred choice for flow regulation and shut-off applications. Understanding the proper installation, operation, maintenance, and selection criteria ensures optimal performance and longevity. By considering the specific application requirements and environmental factors, butterfly valves can provide reliable service for decades.